.png) 400-007-7516

400-007-7516

.png) 400-007-7516

400-007-7516

Filter cylinder purification series

All-in-one high efficiency filter cartridge purifier

Split type high efficiency filter cartridge purifier

Cross mounted high efficiency filter cartridge purifier

Green series high efficiency filter cartridge purifier

Mobile welding smoke filter cartridge purifier

Mill dust collector

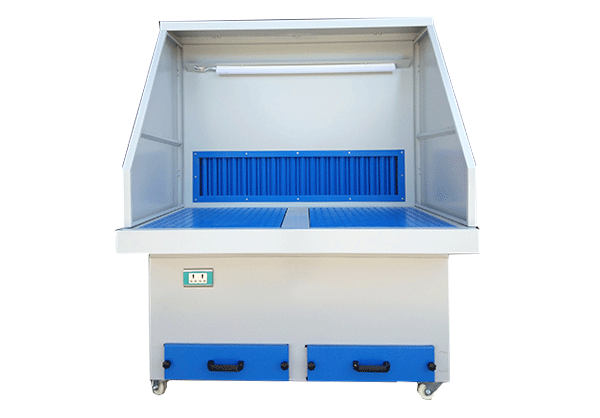

Grinding and dusting table

Fireproof and explosion-proof dust collector

Corrosion resistant dust collector

High negative pressure (high vacuum) dust collection series

Exhaust gas purification series

Cloth bag dust collection series

Accessories and other

200+People like

product details

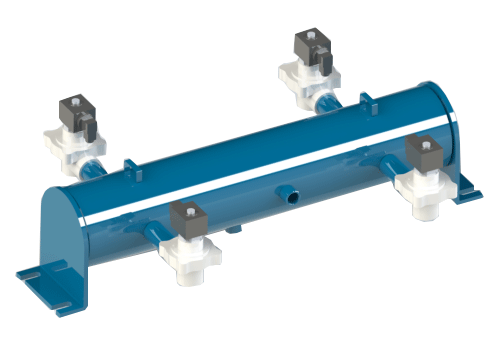

Compressed air bag, solenoid valve

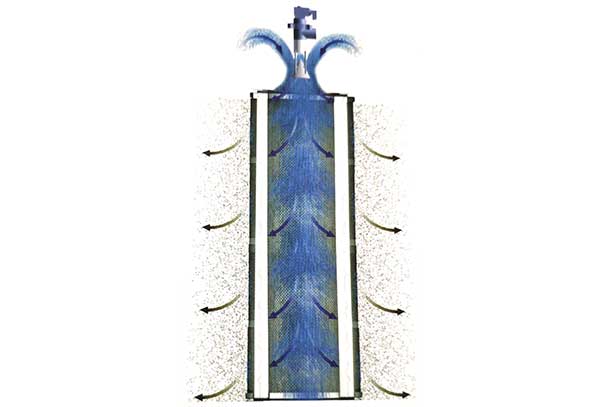

Dust removal schematic diagram

Product parameter

|

Equipment model |

JTDT-2.0 |

JTDT-3.0 |

JTDT-3.0 |

|

Treated air volume(m³/h) |

2000 |

3000 |

4000 |

|

Motor power(KW) |

3.0 |

4.0 |

5.5 |

|

Supply voltage(V/Hz) |

380V/50Hz |

||

|

Cleaning method |

Automatic pulse cleaning |

||

|

Noise(db) |

≤75±5 |

||

|

Filter area(㎡) |

40 |

40 |

56 |

|

Cartridge Quantity (only) |

4 |

||

Engineering case

|

Equipment model |

JTDT-2.0 |

JTDT-3.0 |

JTDT-3.0 |

|

Treated air volume(m³/h) |

2000 |

3000 |

4000 |

|

Motor power(KW) |

3.0 |

4.0 |

5.5 |

|

Supply voltage(V/Hz) |

380V/50Hz |

||

|

Cleaning method |

Automatic pulse cleaning |

||

|

Noise(db) |

≤75±5 |

||

|

Filter area(㎡) |

40 |

40 |

56 |

|

Cartridge Quantity (only) |

4 |

||

After-sales service

The company has a professional technical team, perfect sales network and customer information database, in good faith for customers to do engineering consulting design, equipment production, installation and debugging, technical training and other related pre-sale, sale and after-sales service, to ensure customer satisfaction.

Service concept

Urgent customer's urgent Think what customers think. Satisfy customer needs

Service target

Very service; Everyone is satisfied

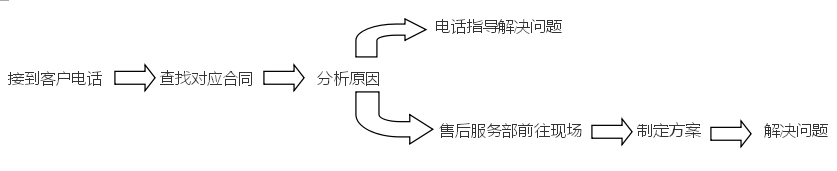

After-sales service process

Performance pledge

Open 24 hours service phone 400-007-7516, at any time to accept user consultation. After-sales service hotline: 18874850576. After receiving customer call, make plan to reply customer within 2 hours. Send experts to the customer's site within 24 hours.